Product Catalogue

System boards

Components of heating and cooling systems

UNDERFLOOR HEATING

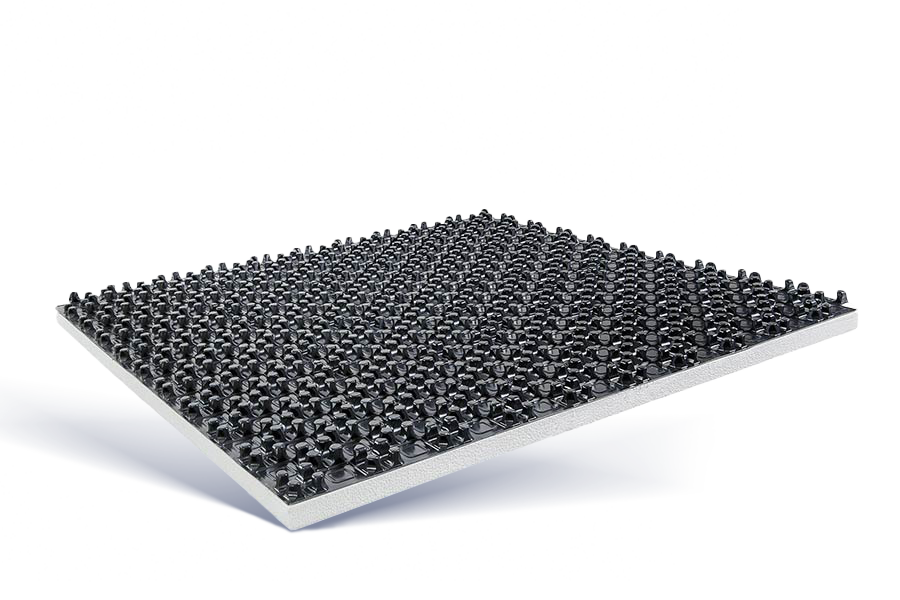

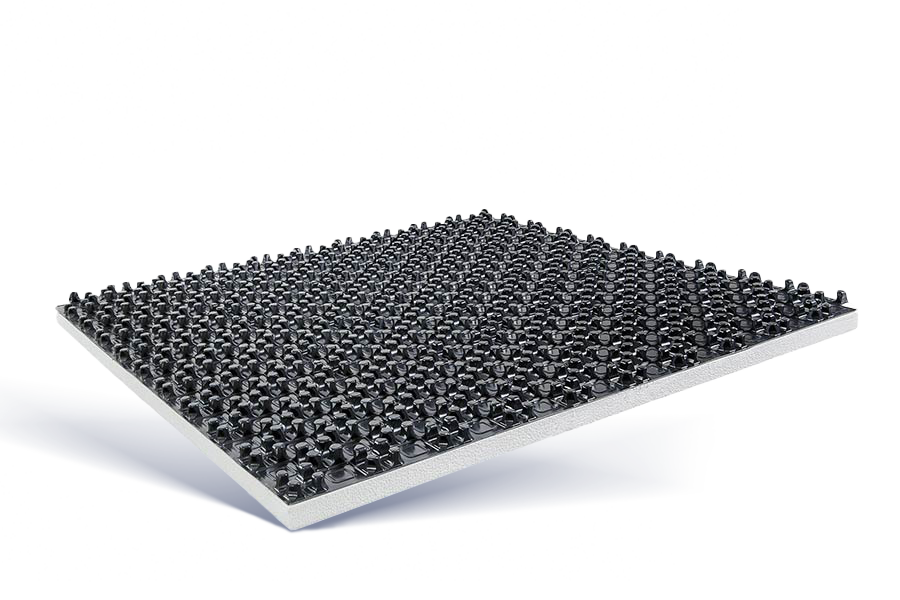

ALMAR SYSTEM DUO

Without insulation

System boards with tabs every 5.0 cm are made of polystyrene film (PS) with a thickness of 1.1 mm, which allows us to perfectly distribute the pipes while maintaining the proper distance and the ability to move on the board. It has anti-slip properties and can be used on thermal insulation and soundproofing. It is a good solution during the renovation of old buildings and newly constructed, where wooden ceilings and beams on joists are used, as well as poured ceilings which cannot be overloaded. They are also suitable where we plan a thin screed of 3.5cm (anhydrite screed) weight 60kg/m2.

The total height of the floor with Almar Duo board is from 3.5-4.5cm as a dry system for underfloor heating is a great alternative for dry underfloor heating. The system can also find its use under traditional screed height of 6-7cm screed weight of 140kg/m2 as a wet system of water floor heating

The overlap in the panel is used to tightly connect the panels, protecting against water from the screed and moisture

Material (PS)

EPS material

Declared heat transfer coefficient -U[W/Mk]:

- 0.038 Material EPS 100 20 [kg/m3]

- 0.035 Material EPS 150 25 [kg/m3]

- 0.033 Material EPS 200 30 [kg/m3]

- 0.045 Material EPS T

Permissible gk load [KNm2] 5.0

Fire classification – according to PNEN 13501-1:F

| Pipe diameter | Dimensions (mm) |

|---|---|

| 14/16/17 | 1000x1000x20 |

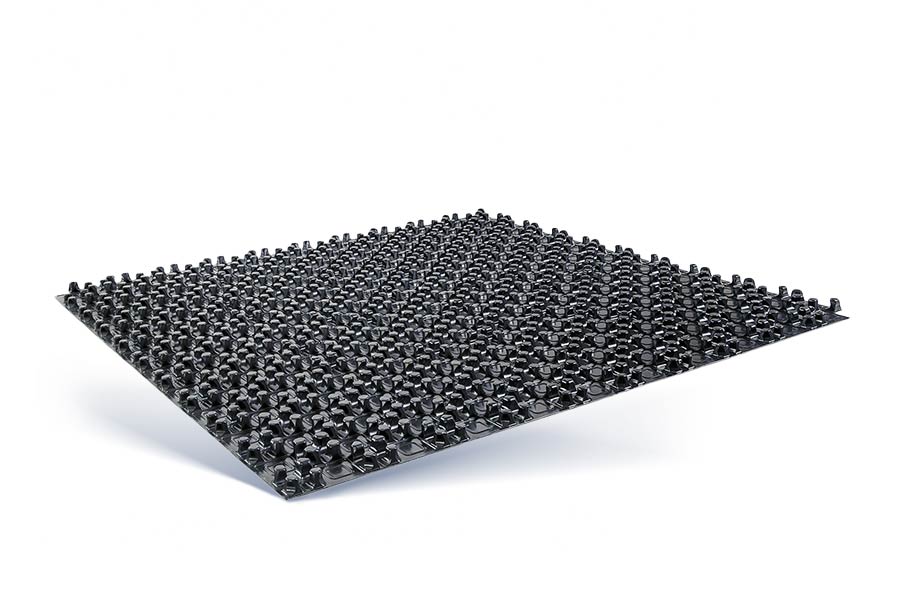

ALMAR SYSTEM DUO

Z insulation

EPS system boards with tabs every 5.0 cm are made of polystyrene foil (PS) with a thickness of 1.1 mm and EPS insulation, which allows us to perfectly distribute the pipes while maintaining the proper distance and the ability to move on the board. Styrofoam board with tabs has good sound insulation with high thermal insulation, anti-slip properties, can be installed in newly constructed buildings where ceilings can take the weight of 140kg/m2, and can find its use in older buildings during renovation is perfectly suitable for anhydrite self-leveling cement screed. The overlap in the board is used to tightly connect the boards, protecting them from screed water and moisture.

Material EPS -Polystyrene

Declared heat transfer coefficient -U[W/Mk]:

- 0.038 Material EPS 100 20 [kg/m3]

- 0.035 Material EPS 150 25 [kg/m3]

- 0.045 Material EPS T

Permissible gk load [KNm2] 5.0

Fire classification – according to PNEN 13501-1:F

| Pipe diameter | Dimensions (mm) |

|---|---|

| 14/16/17 | 1000x1000x10 |

| 14/16/17 | 1000x1000x15 |

| 14/16/17 | 1000x1000x20 |

| 14/16/17 | 1000x1000x25 |

| 14/16/17 | 1000x1000x30 |

ALMAR EPS WITH FOLIA – roll out

System boards EPS PE, PP with ALU coating laminate of polyethylene film and polypropylene film with a thickness of 0.11mm we use as a moisture -thermal and acoustic insulation .The film on the polystyrene has a print in the shape of rectangles, which allow fast and accurate laying of heating pipes .We use self-leveling cement screed on the board.

Density (kg / m3): 20

Declared thermal conductivity coefficient W / ( m * K ) 0.038

Declared thermal resistance R(m*K)/W

- 0.50-20mm

- 0.50 -25mm

- 0.75-30mm

- 1.30-50mm

Permissible gk load (KNm2) 5.0

Fire classification – according to PN EN I3501-1:F

| Material | Thickness | Dimensions (mm) |

|---|---|---|

| EPS 100 | 30/50 | 500×100 |

ALMAR EPS WITH FOLIA – foldable.

System boards EPS PE, PP with ALU coating laminate of polyethylene film and polypropylene film with a thickness of 0.11mm we use as a moisture -thermal and acoustic insulation .The film on the polystyrene has a print in the shape of rectangles, which allow fast and accurate laying of heating pipes .We use self-leveling cement screed on the board.

Density (kg / m3): 20

Declared thermal conductivity coefficient W / ( m * K ) 0.038

Declared thermal resistance R(m*K)/W

- 0.50-20mm

- 0.50 -25mm

- 0.75-30mm

- 1.30-50mm

Permissible gk load (KNm2) 5.0

Fire classification – according to PN EN I3501-1:F

| Material | Thickness | Dimensions (mm) |

|---|---|---|

| EPS 100 | 25/30 | 200×100 |

ALMAR SYSTEM PLUS – power panel

System panels EPS drywall – we use on ceilings of light wooden construction as a load-bearing element for pipes .The panel provides good acoustic and thermal insulation. Panels differ in parameters such as length, width, thickness of the panel ,diameter and distance between pipes.

- Material-EPS 200

- Density (kg / m3): 30

- Declared thermal conductivity coefficient W / ( m * K ) 0.033

- Declared thermal resistance R(m*K)/W

- 0.75 -25mm

- 0.87 -30mm

- 1.44-50mm

- Compressive strength (KPA) 200

- Fire classification – according to PN EN I3501-1:E

| Diameter (mm) | Spacing | Dimensions (mm) |

|---|---|---|

| 16/17 | 125 | 1000x500x25 |

| 16/17 | 125 | 1000x500x30 |

| 16/17 | 125 | 1000x500x50 |

ALMAR SYSTEM PLUS – return panel

System panels EPS drywall – we use on ceilings of light wooden construction as a load-bearing element for pipes .The panel provides good acoustic and thermal insulation. Panels differ in parameters such as length, width, thickness of the panel ,diameter and distance between pipes.

- Material-EPS 200

- Density (kg / m3): 30

- Declared thermal conductivity coefficient W / ( m * K ) 0.033

- Declared thermal resistance R(m*K)/W

- 0.75 -25mm

- 0.87 -30mm

- 1.44-50mm

- Compressive strength (KPA) 200

- Fire classification – according to PN EN I3501-1:E

| Diameter (mm) | Spacing | Dimensions (mm) |

|---|---|---|

| 16/17 | 125 | 1000x500x25 |

| 16/17 | 125 | 1000x500x30 |

| 16/17 | 125 | 1000x500x50 |

ALMAR SYSTEM PLUS EPS- power panel

System panels EPS drywall – we use on ceilings of light wooden structure as a supporting element for pipes .The panel provides good acoustic and thermal insulation. Panels differ in parameters such as length, width, thickness of the panel, diameter and distance between pipes.

- Material-EPS 200

- Density (kg / m3): 30

- Declared thermal conductivity coefficient W / ( m * K ) 0.033

- Declared thermal resistance R(m*K)/W

- 0.80-25mm

- 0.90 -30mm

- 1.50-50mm

- Permissible load gk(KNm2) 2.0

- Fire classification – according to PN EN I3501-1:E

| Diameter (mm) | Spacing (mm) | Dimensions x/y (mm) |

|---|---|---|

| 16/17 | 125/150/200 | 1000x500x25 |

| 16/17 | 125/150/200 | 1000x500x30 |

| 16/17 | 125/150/200 | 1000x500x50 |

| 16/17 | 125/150/200 | 1200x600x25/30/50 |

ALMAR SYSTEM PLUS EPS- return panel

System panels EPS drywall – we use on ceilings of light wooden structure as a supporting element for pipes .The panel provides good acoustic and thermal insulation. Panels differ in parameters such as length, width, thickness of the panel, diameter and distance between pipes.

- Material-EPS 200

- Density (kg / m3): 30

- Declared thermal conductivity coefficient W / ( m * K ) 0.033

- Declared thermal resistance R(m*K)/W

- 0.80-25mm

- 0.90 -30mm

- 1.50-50mm

- Permissible load gk(KNm2) 2.0

- Fire classification – according to PN EN I3501-1:E

| Diameter (mm) | Spacing (mm) | Dimensions x/y (mm) |

|---|---|---|

| 16/17 | 125/150/200 | 1000x500x25 |

| 16/17 | 125/150/200 | 1000x500x30 |

| 16/17 | 125/150/200 | 1000x500x50 |

| 16/17 | 125/150/200 | 1200x600x25/30/50 |

ALMAR SYSTEM PLUS EPS Dubel- return panel

System panels EPS drywall – we use on ceilings of light wooden structure as a supporting element for pipes .The panel provides good acoustic and thermal insulation. Panels differ in parameters such as length, width, thickness of the panel, diameter and distance between pipes.

- Material-EPS 200

- Density (kg / m3): 30

- Declared thermal conductivity coefficient W / ( m * K ) 0.033

- Declared thermal resistance R(m*K)/W

- 0.80-25mm

- 0.90 -30mm

- 1.50-50mm

- Permissible load gk(KNm2) 2.0

- Fire classification – according to PN EN I3501-1:E

| Diameter (mm) | Spacing (mm) | Dimensions x/y (mm) |

|---|---|---|

| 16/17 | 125/150/200 | 1000x500x25 |

| 16/17 | 125/150/200 | 1000x500x30 |

| 16/17 | 125/150/200 | 1000x500x50 |

| 16/17 | 125/150/200 | 1200x600x25/30/50 |

ALMAR SYSTEM BIO- power panel

System boards made of wood fiber (plywood) dry construction – we use on ceilings of light construction as fastening for pipes. The panels provide good thermal and acoustic insulation. The panels differ in parameters such as length, width, thickness of the panel ,diameter and distance between the pipes.

- Material-wood fiber

- Density (kg / m3): 240-270

- Declared thermal conductivity coefficient W / ( m * K ) 0.050

- Declared thermal resistance R(m*)/W 1.0

- Compressive strength (KPA) 100

- Specific heat capacity c (J/kg*K): 2100

- Water vapor diffusion resistance coefficient ʅ : 10 dry conditions; 5 wet conditions

- Sound absorption coefficient: 0.10 for frequencies of 250-500 Hz;

- 0.30 for frequencies of 1000-2000 Hz

- Fire classification – according to PN EN I3501-1:E

| Diameter (mm) | Spacing | Dimensions (mm) |

|---|---|---|

| 16/17 | 150/200 | 1200x600x24 |

| 16/17 | 150/200 | 1200x600x36 |

| 20 | 150/200 | 1200x600x36 |

ALMAR SYSTEM BIO- return panel

System boards made of wood fiber (plywood) dry construction – we use on ceilings of light construction as fastening for pipes. The panels provide good thermal and acoustic insulation. The panels differ in parameters such as length, width, thickness of the panel ,diameter and distance between the pipes.

- Material-wood fiber

- Density (kg / m3): 240-270

- Declared thermal conductivity coefficient W / ( m * K ) 0.050

- Declared thermal resistance R(m*)/W 1.0

- Compressive strength (KPA) 100

- Specific heat capacity c (J/kg*K): 2100

- Water vapor diffusion resistance coefficient ʅ : 10 dry conditions; 5 wet conditions

- Sound absorption coefficient: 0.10 for frequencies of 250-500 Hz;

- 0.30 for frequencies of 1000-2000 Hz

- Fire classification – according to PN EN I3501-1:E

| Diameter (mm) | Spacing | Dimensions (mm) |

|---|---|---|

| 16/17 | 150/200 | 1200x600x24 |

| 16/17 | 150/200 | 1200x600x36 |

| 20 | 150/200 | 1200x600x36 |

ALMAR SYSTEM ORGANIC- power panel

Systemic particleboard (MFP) drywall – we use on lightweight ceilings as a mount for pipes. The board provides good thermal and acoustic insulation. They differ in parameters such as thickness, diameter, distance between pipes.

- Material-particleboard (MFP)

- Density [kg / m3]: 740

- Water vapor diffusion resistance coefficient ʅ : 10 dry conditions; 5 wet conditions

- Swelling after 24 hours contact with water: less than 10 percent

- Fire classification – according to PN EN I3501-1:E D-s2,d0(Dfl-s1 for floors)

| Diameter (mm) | Spacing | Dimensions (mm) |

|---|---|---|

| 16/17 | 150/200 | 1200x600x22 |

| 16/17 | 150/200 | 1200x600x25 |

ALMAR SYSTEM ORGANIC-return panel

Systemic particleboard (MFP) drywall – we use on lightweight ceilings as a mount for pipes. The board provides good thermal and acoustic insulation. They differ in parameters such as thickness, diameter, distance between pipes.

- Material-particleboard (MFP)

- Density [kg / m3]: 740

- Water vapor diffusion resistance coefficient ʅ : 10 dry conditions; 5 wet conditions

- Swelling after 24 hours contact with water: less than 10 percent

- Fire classification – according to PN EN I3501-1:E D-s2,d0(Dfl-s1 for floors)

| Diameter (mm) | Spacing | Dimensions (mm) |

|---|---|---|

| 16/17 | 150/200 | 1200x600x22 |

| 16/17 | 150/200 | 1200x600x25 |

ALMAR SYSTEM GIPSUM- power panel

System boards gypsum-fiber drywall – have excellent application during renovation, restoration of the building. Gypsum-woven board is a good conductor of heat. The panels differ in parameters such as length, width, thickness of the panel ,diameter and distance between the pipes.

- Material-Gypsum fleece

- Density [kg / m3]: 1150

- Declared thermal conductivity coefficient W / ( m * K ) 0.032

- Water vapor diffusion resistance coefficient µ : 13

- Swelling after 24 hours contact with water: <2%

- Fire classification – according to PN EN I3501-1:E

| Diameter (mm) | Spacing | Dimensions (mm) |

|---|---|---|

| 10 | 100 | 1200x600x15 |

| 12 | 120 | 1200x600x18 |

| 12 | 150 | 1200x600x18 |

ALMAR SYSTEM GIPSUM- return panel

System boards gypsum-fiber drywall – have excellent application during renovation, restoration of the building. Gypsum-woven board is a good conductor of heat. The panels differ in parameters such as length, width, thickness of the panel ,diameter and distance between the pipes.

- Material-Gypsum fleece

- Density [kg / m3]: 1150

- Declared thermal conductivity coefficient W / ( m * K ) 0.032

- Water vapor diffusion resistance coefficient µ : 13

- Swelling after 24 hours contact with water: <2%

- Fire classification – according to PN EN I3501-1:E

| Diameter (mm) | Spacing | Dimensions (mm) |

|---|---|---|

| 10 | 100 | 1200x600x15 |

| 12 | 120 | 1200x600x18 |

| 12 | 150 | 1200x600x18 |

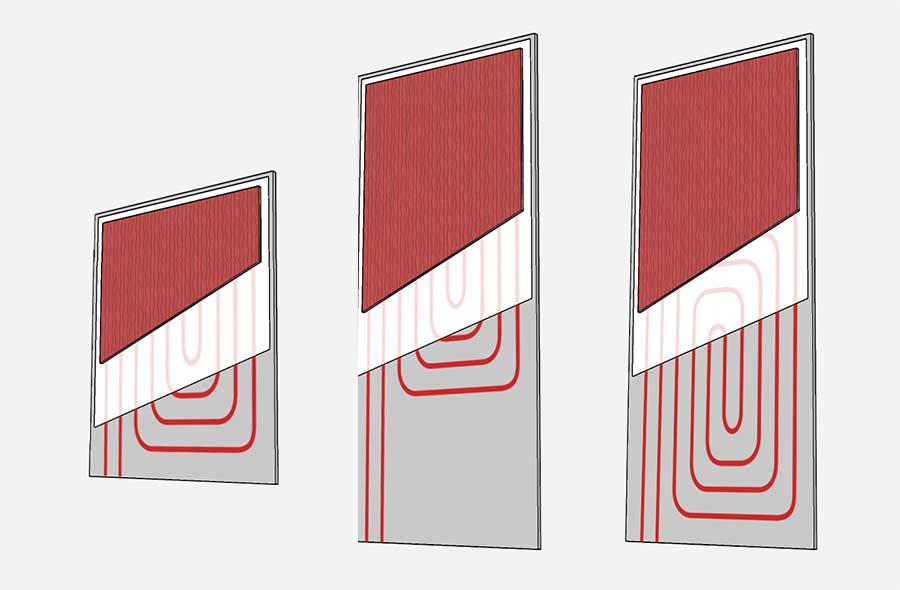

WALL HEATING

ALMAR FACE PANEL-return panel

Wall heating, known as the Wall Heating System, is very similar to underfloor heating in both construction and operation. Basically, one physical difference between the two types of heating is that one is installed in the floors and the other in the walls.

The gypsum-fiber board is dedicated to the installation of walls in the drywall method. Used in both old and new construction serving as a heating or cooling element.

- Material gypsum-woven panel

- Thermal conductivity coefficient U – 0.32 W/M/k

- Maximum working pressure -4 bar

- Heating capacity W/m – 111

- Cooling capacity W/m – 70

- Weight of the panels depending on the thickness from 12 to 30 kg

- Channel spacing 7.5 cm

- Tube diameter 8/10 mm

| Diameter (mm) | Spacing | Dimensions (mm) |

|---|---|---|

| 10 | 100 | 1200x600x15 |

| 12 | 120 | 1200x600x18 |

| 12 | 150 | 1200x600x18 |